Jakarta, January 5, 2022 – Pollution that affect our environment are still a problem that must be addressed by many parties. Most of modern factories takes an active part in maintaining the balance and availability of natural resources through production processes that are in accordance with sustainable principles, or if referring to the idea by the Government of Indonesia through the Ministry of National Development Planning, the industrial sector is also expected to start playing an active role in implementation of a circular economy.

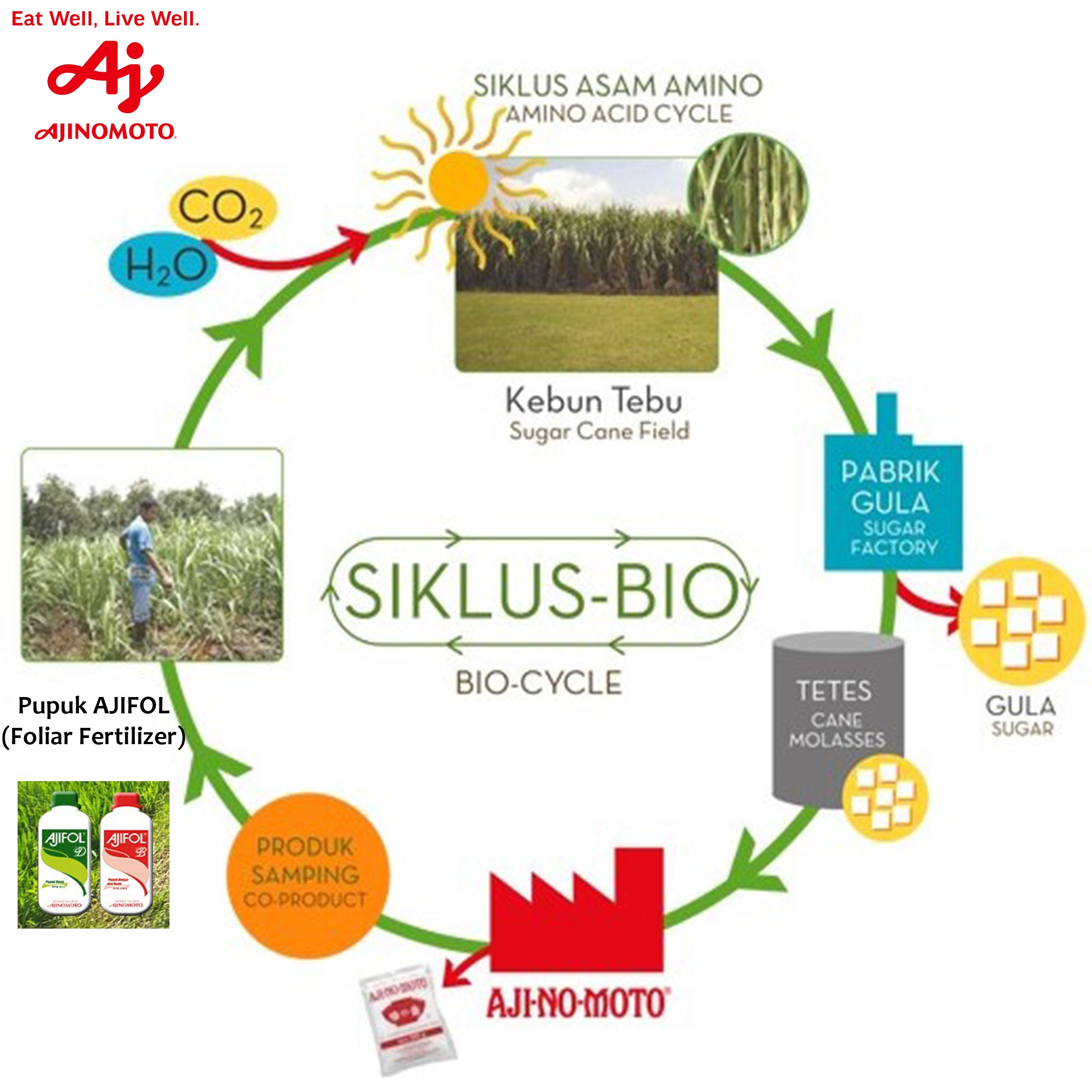

In every product produced, PT AJINOMOTO INDONESIA applies an environmental friendly production process. PT AJINOMOTO INDONESIA's factory in Mojokerto has made various efforts to achieve Zero Waste which is an effort to minimize and reduce environmental pollution to zero. Various efforts have been made including reducing carbon emissions, reducing water consumption, implementing Bio-Cycle & Eco-Activity which produces co-products such as AJIFOL Fertilizer, AMINA, FML (animal feed raw materials), and improving waste water management so that when it is channeled to the Brantas River the quality becomes good and the water becomes better and cleaner.

"In addition to processing liquid by-products from MSG production, we at the Agriculture Development (Agri Dev) Department are also responsible for processing solid by-products and several other domestic wastes into GCC Mix soil conditioner, TRITAN animal feed materials, and some of other co-products that have selling points,” said Yudho Koesbandryo, Factory Manager and Director of PT AJINOMOTO INDONESIA.

"In addition to the co-product manufacturing process that applies Bio-Cycle & Eco-Activity, PT AJINOMOTO INDONESIA also implements many environmental friendly production activities such as reducing 38,500 tons of carbon emissions (CO2) in various ways, such as reducing fuel consumption throughout transportation at work, reduce the use of electricity, and overcome steam leaks in production equipment. We have a target in reducing 180.000 tons of CO2 by 2023," continued Yudho.

PT AJINOMOTO INDONESIA is also committed to support environmental conservation by reducing water use by up to 35% by making savings through water quality improvement in every production activity. This commitment is also a form of participation in the success of the Indonesian Government's environmental conservation program and in line with Ajinomoto Co., Inc's target to reduce environmental impact by up to 50%. This step also aims to maintain the availability of water on a regional scale, so that it can help overcome limited water resources due to increased water consumption, especially during the pandemic.

“We are actively working on reduce, reuse, recover, and recycle activities for water use in most of our activities. This is quite encouraging, because even by reducing water use by up to 35%, the production capacity of MSG (Monosodium Glutamate) and other seasonings still increasing," said Yudho.

Through these movements, PT AJINOMOTO INDONESIA hopes to inspire many parties to carry out other movements aimed at preserving the environment. PT AJINOMOTO INDONESIA is committed to continue in a positive contribution for the society, by improving the welfare and health of Indonesian families through high quality products and services.