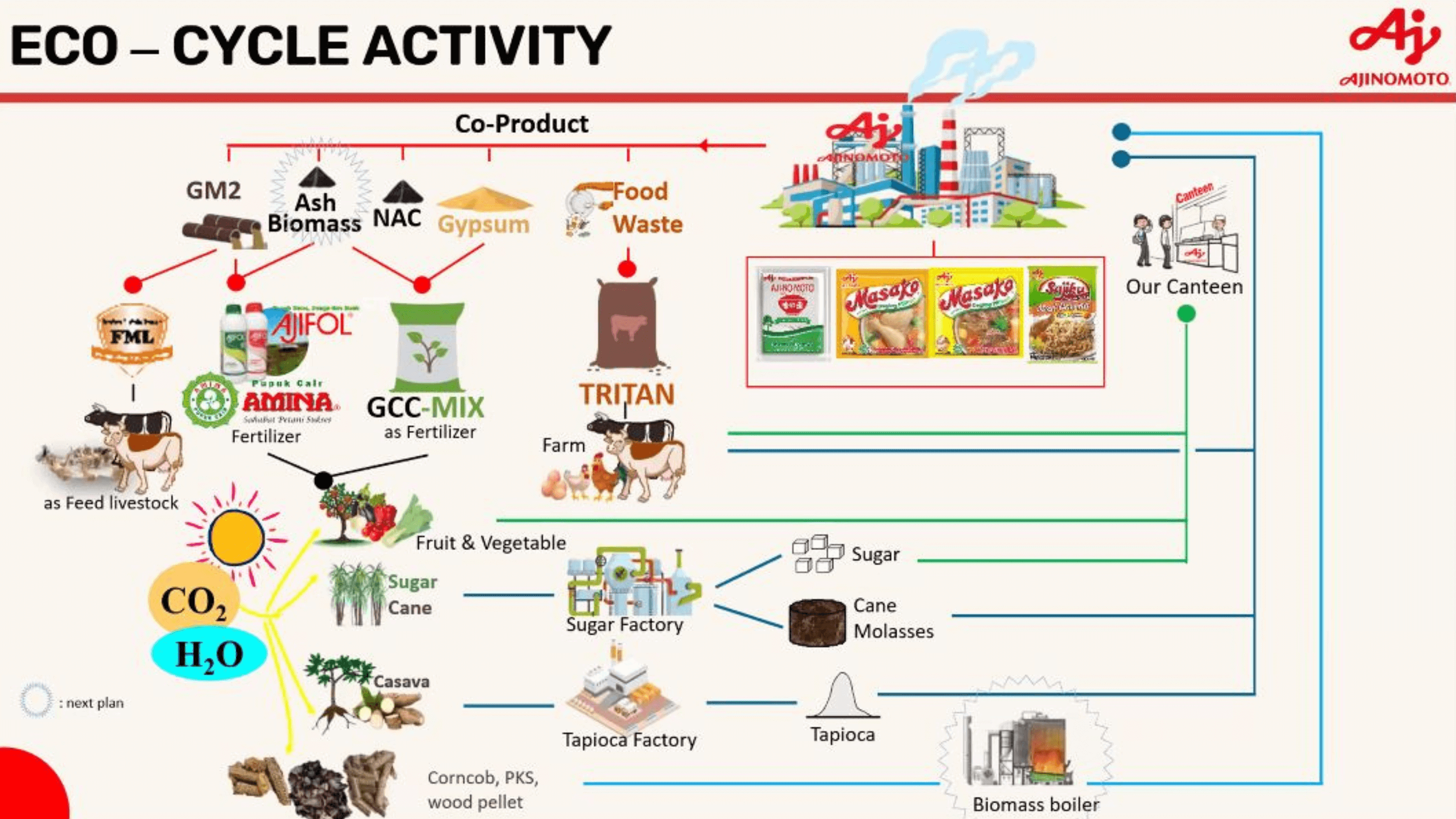

Jakarta, August 25, 2022 - PT AJINOMOTO INDONESIA (Ajinomoto) practices circular economy to create an environmentally friendly production process. The Ajinomoto factory in Mojokerto has made various efforts to achieve Zero Waste, which is an effort to minimize and reduce environmental pollution to zero. Various efforts have been made including reducing carbon emissions, reducing water consumption, implementing Bio-Cycle & Eco-Activity which produces co-products such as AJIFOL Fertilizer, AMINA, and FML animal feed raw materials. to the Brantas River the water quality is better and cleaner.

The concept of a circular economy is related to one of the policies rolled out by the Ministry of Industry, namely the green industry. The implementation of the green industry seeks efficiency and effectiveness in the use of resources in a sustainable manner so as to be able to harmonize industrial development with the preservation of environmental functions and can provide benefits to the community so as to be able to harmonize industrial development with the preservation of environmental functions and can provide benefits to the community. The development of a circular economy brings opportunities for a number of industrial sectors in Indonesia, including Ajinomoto.

“Ajinomoto practices a circular economy. We always maintain and improve production efficiency from upstream to downstream in the existing production process. Upstream, with the technology we have, we reduce the use of raw materials to increase productivity. In the process until it reaches its downstream, we produce co-products or by-products that have a selling value and can be applied in agriculture and livestock. In addition to processing liquid by-products from MSG production, our Agriculture Development (Agri Dev) Department is also responsible for processing solid by-products into GCC Mix soil enhancer, TRITAN animal feed material, and several other co-products that also have value. sell,” said Yudho Koesbandryo, as Director of PT AJINOMOTO INDONESIA when attending the Waste Care Festival Webinar organized by the Indonesian Ministry of Environment & Forestry (KLHK).

"In addition to the co-product manufacturing process that applies Bio-Cycle & Eco-Activity, Ajinomoto also implements many environmentally friendly production activities such as reducing 34,900 tons of carbon emissions (CO2) in various ways such as reducing fuel consumption throughout transportation at work, cutting use of electricity, and overcome steam leaks in production equipment. We have a target of reducing 180,000 tons of CO2 by 2023, from the 2018 based line. Then, in the future, we will too," continued Yudho.

Ajinomoto is also committed to supporting environmental conservation by reducing water use by up to 31%, from the 2016 based line, by making savings through improving water quality (water treatment) in production activities. This commitment is also a form of Ajinomoto's participation in the success of the Indonesian Government's environmental conservation program and is in line with Ajinomoto Co., Inc aspiration to help reduce environmental impacts by up to 50%. This step also aims to maintain the availability of water on a regional scale, so that it can help overcome limited water resources due to increased water consumption, especially during the pandemic.

“We are actively working on reduce, reuse, recover, and recycle activities for water use in every activity. This is quite encouraging, because even by reducing water use by up to 31%, the production capacity of MSG and other seasonings can still increase,” said Yudho.

“Then, another environmental problem in Indonesia is the amount of plastic waste which is piling up from year to year. Highlighting this problem, Ajinomoto also took concrete steps. The MSG AJI-NO-MOTO® brand, which is closely related to the daily life of Indonesian families, contributes to overcoming the problem of plastic waste accumulation by reducing up to 30% the use of plastic materials in its packaging,” he continued.

It was for this initiation that the AJI-NO-MOTO® MSG Brand earned the MURI record as the first MSG seasoning in Indonesia with environmentally friendly packaging. In addition, PT AJINOMOTO INDONESIA also reduces the use of plastic in other products such as: 8.4% Masako® in each 9gr package and 9.5% Sajiku® in each package, and further research will be carried out in the future so that we can continue to suppress the use of plastic materials in each product.

We try to carry out these activities in 3 parts, upstream (related to sustainability, for example resources), midstream (efficiency and stability) and downstream (benefits for communities and customers). Currently our largest portion is in the upstream and midstream because it is our baseline, but starting in 2022 we have made a feasibility study and roadmap for downstream. In terms of downstream activities we need more and more partners for collaboration.

Through these steps, Ajinomoto hopes can inspire many parties to carry out other movements aimed at preserving the environment. Ajinomoto is committed to continuing to make a positive contribution to society, by improving the welfare and health of Indonesian families through high quality products and services.